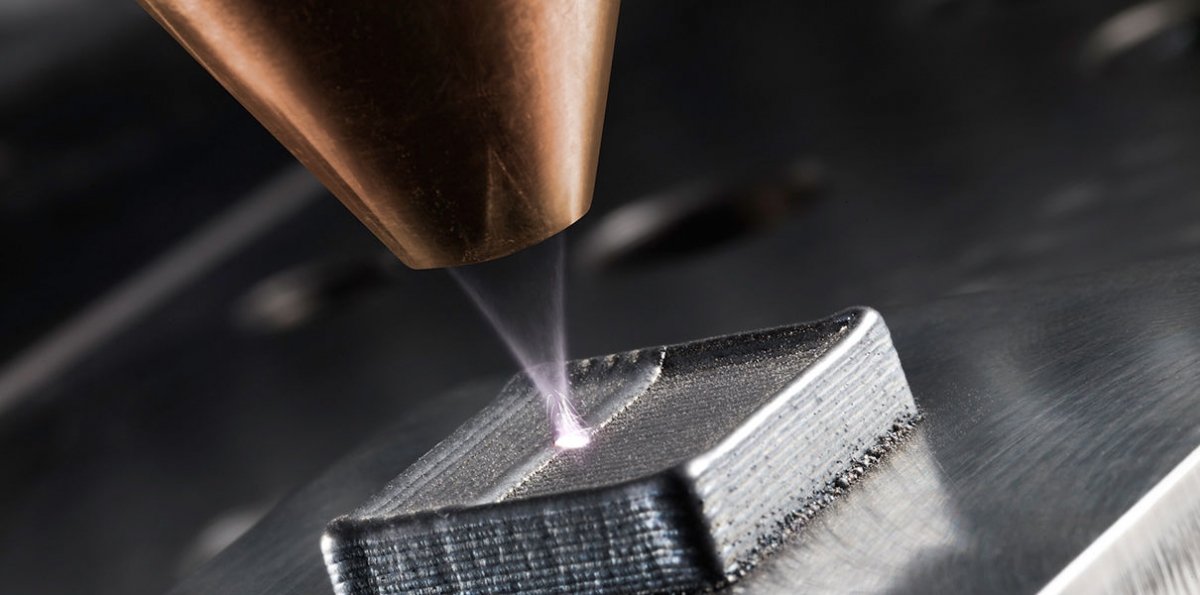

Metal 3D printing is changing the way we produce components. In reduced to mid-volume industrial runs, the pieces can be made faster, cheaper, and with reduced initiative than standard production processes. Considering that additive manufacturing kinds parts differently, it makes it a lot easier to generate specific types of elements that need intricate features. The procedure uses no tooling, is practically fully automated, and enhances instead of getting rid of materials to enable more improved geometries.

Nowadays, there are multiple effective ways to produce a three-dimensional element for an item. The most common is to use metal 3D printers to develop the component. Yet it would be best if you also decided which material you will use. You could, as an example, make use of a sort of plastic to produce your 3D version, but metal 3D printing is feasible and possibly much more helpful.

Metal 3D Printers: What are the Advantages?

A vital benefit of 3D printing with the help of metal is that it can be used to establish complex and bespoke items. These components can have geometries that merely cannot be created by utilizing manufacturing processes that are commonly seen as even more traditional than 3D printing. On top of that, the steel items made with the help of 3D printers usually have special physical requirements.

Moreover, the offered variety of steel materials that can be utilized includes types that are usually rather hard to process. Another advantage of the 3D published components constructed out of steel is that they can be topologically maximized. By doing this, their performance will undoubtedly be taken full advantage of while their weight will certainly be decreased. Metal superalloys are excellent instances of this advantage.

Are there Limitations?

However, 3D publishing a metal has some negative aspects too. As an example, if you have currently created a layout, this could not be appropriate for metal 3D printing. As a result, you would certainly need to adjust and alter the three-dimensional version.

The production costs are high, similar to the price to pay for the products. In addition, metal 3D printing typically sets you back fairly a great deal. If you can get rid of a traditional technique, this might be much better, considering that it is most likely less expensive than metal 3D printing.

Metal 3D printing systems likewise do not have the most extensive construct sizes. This is restricting, given that specific procedure control and manufacturing conditions are required. Lastly, metal 3D printing requires a more incredible amount of skill and also expertise than standard plastic printing. Nonetheless, this can be countered by working with a 3D printing solution that will have the knowledge and experience to help you.

Rule of Thumb

Metal 3D printing is most ideal for a facility, bespoke components that are difficult or highly pricey to make with traditional approaches. Decreasing the requirement for support frameworks will substantially reduce the cost of steel printing. Topology optimization is crucial for making the most of the added advantages of using metal printing. Metal 3D printed components have exceptional mechanical homes and can be made from a wide range of design products consisting of steel superalloys.